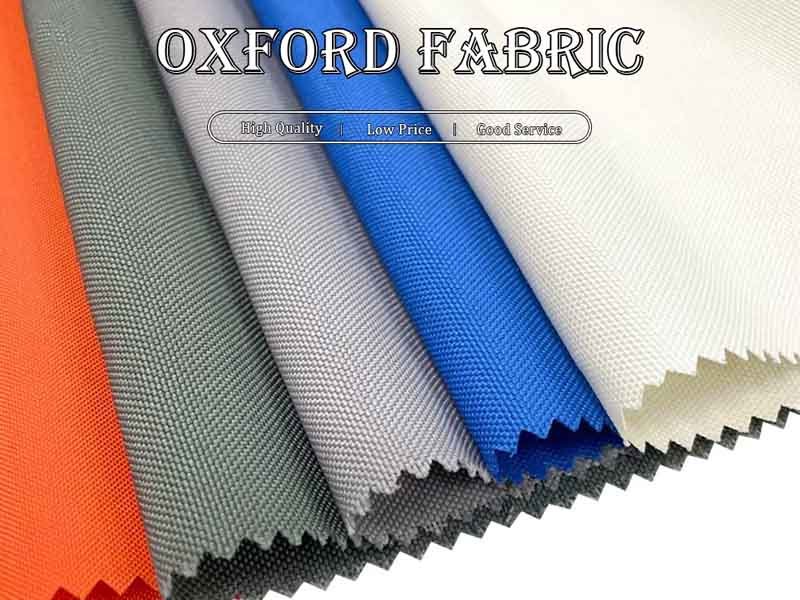

Oxford cloth is everywhere—from your favorite button-down shirt to the backpack you sling over your shoulder each morning. Yet few pause to consider what gives this fabric its distinctive texture, durability, and adaptability. Originally woven for men’s shirts in 19th-century Scotland, Oxford cloth has since evolved into a heavyweight contender in the bag manufacturing world, thanks to its unique weave and finish options that range from casual softness to robust, water-resistant performance.

Oxford cloth is a plain or basket weave fabric traditionally made from cotton or cotton-poly blends. Its signature “basket” structure—pairing two weft threads over two warp threads—creates a slack, textured surface that balances breathability with strength. Modern variants include polyester, nylon, and coated finishes (PU, PVC, DWR) for water resistance. Oxford’s versatility makes it ideal for everything from dress shirts to rugged totes and backpacks.

Imagine ordering a custom Oxford backpack from Szoneier—its rich weave catching the light as you unroll it in a Parisian café, the PU-coated surface shrugging off a surprise drizzle. This guide unpacks Oxford cloth’s DNA, guiding you to the perfect fabric choice for your brand’s next bag collection.

What Is Oxford Cloth and How Is It Made?

Oxford cloth is woven in a basket or plain weave, pairing multiple weft threads over multiple warp threads. Traditionally 100% cotton, modern versions blend polyester or nylon. Yarn counts and weaving tension define weight (4–10 oz/yd²). After weaving, the fabric undergoes scouring, bleaching, and optional mercerizing for strength and sheen. Optional coatings (PU, PVC, DWR) add water resistance, tailoring Oxford for both apparel and bag applications.

Understanding Oxford cloth’s journey—from raw fiber to coated fabric—reveals why it’s prized for custom bags that require both aesthetics and performance.

1. Yarn Selection and Preparation

Fiber Choices:

- Cotton: Soft hand, excellent dye affinity, breathable.

- Cotton–Polyester Blends: Enhanced UV and mildew resistance; reduced shrinkage.

- Nylon Blends: Added tensile strength and abrasion resistance for heavy-duty uses.

Yarn Counts: Measured in Ne (cotton) or denier (synthetics). Typical Oxford uses 40s–60s Ne cotton or 100–200D synthetics, balancing weight and tactile quality.

2. Weaving Techniques

Basket Weave (2×2):

- Two weft yarns interlace over two warp yarns, producing the signature “checkerboard” texture.

- Yields a softer, more breathable fabric with gentle drape—ideal for bags carried close to the body.

Plain Weave Variant (1×1):

- Simpler interlacing; used in lighter, pinpoint Oxfords for a smoother, finer finish.

Weaving occurs on rapier looms—for high-speed, large-volume production—or shuttle looms, which produce denser selvedges prized in premium fabrics.

3. Wet-Processing Steps

Scouring:

- Removes natural oils, waxes, and sizing agents, ensuring uniform finish application.

Bleaching:

- Creates a bright base for dyeing; critical for consistent coloration in branded bags.

Mercerizing (Optional):

- Treating cotton yarns with sodium hydroxide enhances tensile strength, luster, and dye uptake—resulting in vibrant, long-lasting colors.

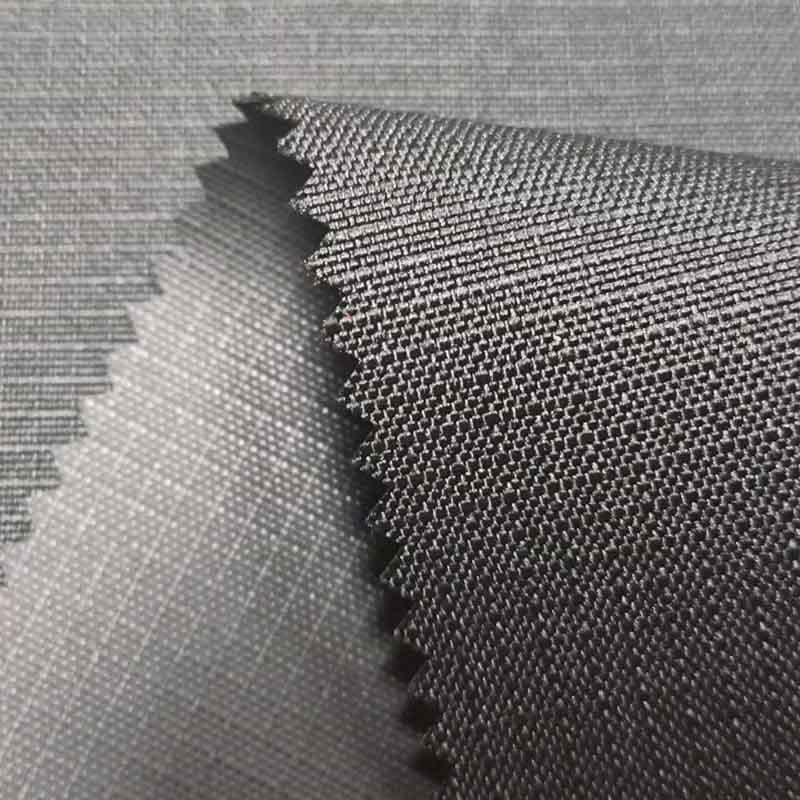

4. Dry Finishing & Coating

Calendering:

- Passing the fabric between heated rollers to smooth the surface and set thickness—improves print clarity and coating adhesion.

Coating Options:

- PU Lamination: Backside waterproofing (20–30% added weight) for dry bags and medical carriers.

- PVC Coating: Heavy-duty, easy-clean surface for cooler bags—adds rigidity.

- DWR Treatments: Fluorine-free or C6 chemistries for lightweight water repellency—preserves breathability and hand feel.

5. Quality Control and Inspection

After finishing, fabrics undergo rigorous checks:

- Grammage Verification: Ensures target GSM (e.g., 200–340 gsm for bag grades).

- Coating Uniformity: Tests for pinholes or uneven coverage, critical for waterproof applications.

- Color Fastness: Assessed via wash/rub tests to guarantee logo and print durability.

6. Customization for Bag Manufacturing

Szoneier integrates Oxford cloth with bespoke features:

- Printed or Embossed Logos: Leveraging the basket weave’s texture for standout branding.

- Lamination Patterns: Strategically placing PU coatings on pockets or base panels.

- Hybrid Constructions: Combining Oxford bodies with canvas or ripstop reinforcements in high-wear zones—achieving optimal weight-to-strength ratios.

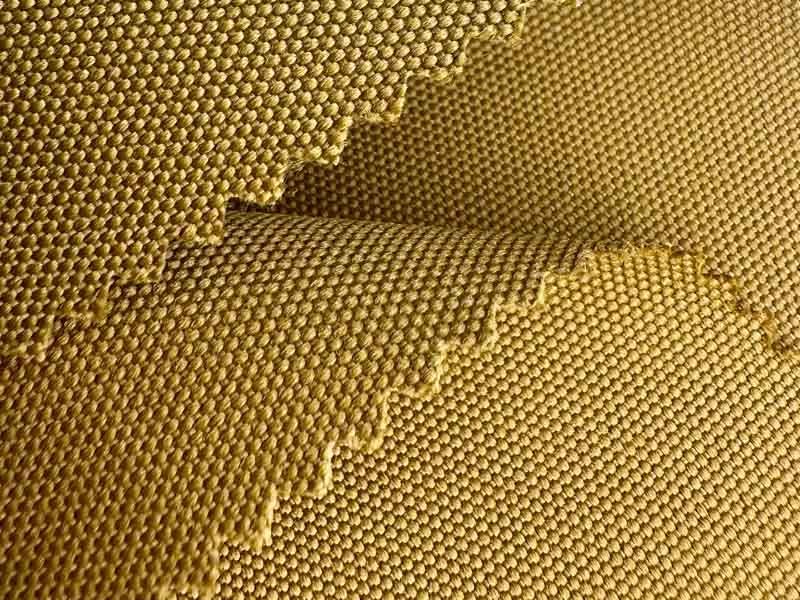

What is The D Rating of Oxford cloth?

“D” in Oxford cloth refers to the denier of the yarn—that is, the weight in grams of 9,000 meters of fiber. Oxford weaves used for bags typically range from 210D up to 600D, with some heavy-duty versions hitting 1000D. Here’s how the most common ratings guide:

210D Oxford (210 denier):

- Yarn weight ~210 g per 9 km.

- Lightweight, soft hand, used in ultralight daypacks, apparel, and pouches.

300D–330D Oxford:

- Yarn weight ~300 g per 9 km.

- Midweight balance of durability and drape—common in commuter backpacks and gym bags.

600D Oxford:

- Yarn weight ~600 g per 9 km.

- Heavy-duty, abrasion-resistant; standard for travel duffels, cooler bags, and work totes.

1000D Oxford:

- Yarn weight ~1000 g per 9 km.

- Extra-rigid, highly tear-resistant—used in tactical packs and industrial applications.

Choosing the Right Denier:

- Light loads & packability: 210D–300D

- Everyday carry & moderate wear: 300D–600D

- Heavy loads & rugged use: 600D–1000D

At Szoneier, we offer Oxford cloth in all these deniers—along with custom blends and coatings—to perfectly match your bag’s intended use and your brand’s quality standards.

Which Fibers and Weave Variations Define Oxford Cloth?

Oxford cloth is defined by its basket (2×2) or plain (1×1) weave and by the fibers it uses—most commonly cotton, polyester, nylon, or blends thereof. Variations include pinpoint Oxford (finer basket weave), royal Oxford (uneven yarn weights), and split Oxford (different warp/weft pairs). Fiber choice and weave dictate texture, durability, dye uptake, and drape, allowing tailored performance from soft shirting to rugged bag fabrics.

1. Natural vs Synthetic Fibers

Cotton Oxford

- Properties: Soft, breathable, excellent dye absorption.

- Yarn Counts: Typically 40s–60s Ne; two-ply for richer hand.

- Applications: Casual and dress shirts, lifestyle backpacks, cosmetic pouches.

- Advantages: Natural feel, sustainable when organic cotton (GOTS-certified).

- Trade-Offs: Moderate abrasion resistance; prone to mildew if left damp.

Polyester & Polyester-Blended Oxford

- Properties: UV-resistant, mildew-proof, low shrinkage.

- Denier Range: 75D–150D; single-ply or plied against cotton.

- Applications: Outdoor gear, tote bags, cooler liners.

- Advantages: Durability and dimensional stability; cost-effective.

- Trade-Offs: Less breathable; potential synthetic sheen.

Nylon Oxford

- Properties: High tensile strength, excellent abrasion resistance.

- Denier Range: 100D–200D in fine dress Oxfords; up to 500D in bag grades.

- Applications: Travel duffels, motorcycle panniers, tactical packs.

- Advantages: Lightweight yet tough; quick-drying.

- Trade-Offs: Can feel “slick”; more expensive than cotton blends.

Blended Yarns

- Cotton–Polyester: Balances softness and performance; reduces wrinkle and shrinkage.

- Cotton–Nylon: Enhances tear strength while maintaining cotton’s hand-feel.

- Recycled Blends: rPET and recycled cotton variants for eco-friendly lines.

2. Weave Variations

Basket Weave (Classic Oxford)

- Structure: Two weft yarns cross two warp yarns (2×2).

- Result: Checkerboard texture, soft drape, high breathability.

- Use Cases: Shirt cloth, light to midweight bags requiring comfort.

Plain Weave Oxford

- Structure: Traditional 1×1 interlace; tighter surface.

- Result: Smooth face, moderate drape.

- Use Cases: Pinpoint Oxford shirts, pouches needing fine print detail.

Pinpoint Oxford

- Structure: Two finer weft yarns per warp, tighter basket.

- Result: Smoother, denser fabric—crisper drape.

- Use Cases: Premium shirting, high-resolution printed bags.

Royal Oxford

- Structure: Alternating yarn sizes (e.g., two coarse, one fine).

- Result: Subtle texture with a lustrous sheen.

- Use Cases: Luxury bags, high-end fashion accessories.

Split Oxford

- Structure: Different yarn counts in warp vs. weft (e.g., heavier weft).

- Result: Unique surface pattern; enhanced durability in one direction.

- Use Cases: Reinforced bag panels, fashion applications requiring visual interest.

3. Impact on Performance and Aesthetics

- Texture & Hand-Feel: Basket weaves yield coarser, tactile surfaces; pinpoint and royal weaves feel smoother.

- Durability: Synthetic fibers and tighter weaves enhance abrasion resistance; coarser weaves allow more flex but can snag.

- Dye & Print Quality: Smooth plain-weave surfaces accept detailed prints; textured basket weaves diffuse prints for a matte look.

- Drape & Structure: Lightweight Oxfords drape like shirting; heavier, synthetic Oxfords hold shape in structured bags.

4. Choosing the Right Oxford Variant

- For Fashion-Forward Bags: Pinpoint or royal Oxford in cotton–poly blends offers print clarity and a refined drape.

- For Rugged Gear: Nylon Oxford 200D–500D with basket weave combines tear resistance and breathability—suitable for travel packs.

- For Eco-Lines: Organic cotton or hemp–cotton splits in classic basket weave underline sustainability messaging.

- For Specialty Coatings: Ensure weave openness accommodates PU or PVC coatings without compromising hand-feel.

What Is the Difference Between Oxford Cloth and Cotton?

While Oxford is often cotton-based, “cotton” refers broadly to any fabric from cotton yarns. Oxford’s basket weave gives unique softness and texture, unlike plain-woven cotton shirting or twill denim. Thus, not all cotton fabrics qualify as Oxford.

How Do Oxford Cloth Weights and Coatings Impact Performance?

Oxford cloth weights range from 4 oz/yd² (lightweight shirts and pouches) to 10 oz/yd² (heavy-duty bags). Coatings—PU laminate adds full waterproofing, PVC boosts durability but reduces flexibility, and DWR keeps fabric breathable while repelling light rain. Weight determines structure and load capacity; finish choice balances water resistance, hand-feel, and cost.

Fabric weight and finish choices directly affect bag performance, manufacturing complexity, and cost.

Weight Classifications

| Category | Weight (oz/yd²) | GSM Approx. | Characteristics |

|---|---|---|---|

| Lightweight Oxford | 4–6 | 135–200 | Soft drape, packable, low structure |

| Midweight Oxford | 6–8 | 200–270 | Balanced strength & flexibility |

| Heavyweight Oxford | 8–10 | 270–340 | Structured, high abrasion resistance |

- Lightweight (4–6 oz): Ideal for lightweight drawstrings, cosmetic pouches, promotional totes.

- Midweight (6–8 oz): Suited to everyday backpacks, gym bags, casual travel packs.

- Heavyweight (8–10 oz): Fits structured travel duffels, cooler bags, and industrial carriers.

Waterproof & Protective Finishes

PU Lamination:

- Method: Laminating a thin polyurethane film on the fabric’s reverse.

- Effect: Fully waterproof, but sacrifices breathability and adds 20–30% weight.

PVC Coating:

- Method: Applying PVC plastisol to one or both sides.

- Effect: High abrasion resistance and easy cleaning; results in a thicker, less flexible fabric.

DWR (Durable Water Repellent):

- Method: Applying a hydrophobic treatment to the fabric face.

- Effect: Lightweight, breathable water beading; wears off over time and requires reproofing.

Is Oxford Fabric Waterproof?

Out of the loom, Oxford cloth is not waterproof—it wicks moisture due to its cotton or open-weave construction. Water resistance only comes from finishes:

- Untreated Oxford: Absorbs water quickly—suits dry climate or light-use fashion bags.

- DWR-Treated: Repels drizzle; insufficient for full rain protection.

- PU/PVC-Coated: True waterproofing—used in cooler bags, medical carriers, and rain-ready duffels.

What Are the Main Advantages and Disadvantages of Oxford Cloth?

Oxford cloth offers soft drape, breathability, and distinctive texture from its basket weave, balancing strength (6–10 oz) with comfort. It accepts coatings and prints well. However, it can absorb moisture, fade in UV, and lack rigidity compared to canvas. Heavy PU/PVC coatings solve waterproofing but add bulk and reduce hand-feel.

Examining Oxford cloth’s pros and cons helps align fabric choice with product goals.

Key Advantages

- Soft Drape & Comfort: Basket weave yields more flexibility than canvas—pleasant against the body.

- Breathability: Natural cotton fibers wick moisture away through the weave—ideal for gym bags and casual packs.

- Surface Receptivity: Smooth basket weave accepts vibrant prints, embroidery, and leather trim attachments.

- Versatility: Fiber and finish options span from lightweight fashion to robust, coated industrial variants.

Drawbacks

- Moisture Absorption: Untreated Oxford increases weight when wet; prone to mildew without proper drying.

- UV Fading: Natural fibers degrade under prolonged sun exposure; dyed fabrics may fade unevenly.

- Limited Rigidity: Even heavyweight Oxford lacks the stiffness of canvas for structured silhouettes.

- Coating Trade-Offs: Heavy coatings solve water issues but add 20–30% weight, reduce breathability, and increase fabrication complexity.

Is Oxford Cloth the Same as Canvas?

While both use plain-weave variants, Oxford cloth’s basket weave and lighter weight (4–10 oz) differentiate it from canvas’s heavier plain or duck weave (7–16 oz). Canvas holds sharper structure; Oxford offers softer drape and superior printability.

What Applications Make Oxford Cloth Ideal for Bags?

Oxford cloth’s balanced strength, soft drape, and ability to accept coatings make it perfect for a wide range of bags—from lightweight promotional totes and cosmetic pouches (4–6 oz) to midweight everyday backpacks and gym duffels (6–8 oz). Heavier (8–10 oz) travel duffels, cooler bags, and medical carriers benefit from PU or PVC coatings on Oxford. Specialty blends (aramid, activated carbon) create fire-resistant or smellproof bags, showcasing Oxford’s versatility across markets.

1. Promotional & Lifestyle Bags

Lightweight Totes (4–6 oz):

- Use Case: Event giveaways, brand merchandise, reusable shopping bags.

- Why Oxford: Soft hand-feel and drape create an approachable, everyday accessory. The basket weave texture adds subtle visual interest without premium cost.

- Customization: Screen printing, heat transfer, or embroidery deliver high-impact branding. Minimal coating (DWR) preserves breathability while resisting light stains.

Cosmetic & Accessory Pouches:

- Use Case: Makeup bags, tech gadget sleeves, travel organizers.

- Why Oxford: Flexibility and light structure conform to contents. PU-laminated or silicone-coated interiors resist spills and are easy to wipe clean.

- Design Tip: Contrast lining fabric for aesthetics and functional visibility of contents.

2. Everyday Carry & Commuter Packs

Backpacks & Gym Duffels (6–8 oz):

- Use Case: Daily commuters, gym-goers, students.

- Why Oxford: Midweight cloth balances durability with comfortable wear. DWR finishes repel drizzles; PU-laminated pockets protect electronics.

- Functional Features: Reinforced base panels, mesh ventilation on back panels, and ergonomic straps extend Oxford’s utility.

Messenger & Sling Bags:

- Use Case: Urban professionals needing quick access.

- Why Oxford: Soft panels rest comfortably against the body; pinpoint or royal variants add subtle sophistication. Coated exteriors handle city elements.

3. Travel & Outdoor Gear

Travel Duffels & Weekenders (8–10 oz):

- Use Case: Weekend trips, carry-on luggage.

- Why Oxford: Heavier weights hold shape under load while remaining lighter than canvas. PU or PVC coatings create waterproof exteriors that stand up to airport conveyor belts.

- Durability Enhancements: Cordura or reinforced Oxford on stress zones; YKK water-resistant zippers for full weather protection.

Cooler & Dry Bags:

- Use Case: Food transport, kayaking, beach outings.

- Why Oxford: PVC-coated Oxford is easy to sanitize, resists mold, and maintains structural integrity when wet.

- Design Note: Seam-taped construction ensures leak-proof performance.

4. Specialized & Niche Applications

Medical & Lab Carriers:

- Use Case: Equipment kits, specimen transport.

- Why Oxford: PU-laminated interiors provide a hygienic, wipe-clean surface. DWR-treated exteriors protect against spills and splashes.

- Compliance: Use FDA-grade coatings and antimicrobial finishes where required.

Fire-Resistant & Smellproof Bags:

- Use Case: Protective tool kits, hunting, hazardous-material transport.

- Why Oxford: Blending aramid fibers (Kevlar®) with cotton Oxford yields flame-retardant panels. Activated-carbon laminated Oxford blocks odors for smellproof applications.

- Certification: UL94 compliance for fire safety; ISO 20743 antibacterial testing for odor control.

5. Aesthetic & Brand Positioning

Oxford’s weave and finish versatility support diverse brand narratives:

- Heritage Appeal: Natural cotton Oxford with waxed finish evokes classic leather-canvas duffel looks.

- Tech-Forward: Nylon Oxford in a pinpoint weave with PU coating conveys minimalist, high-performance ethos.

- Eco-Luxury: Organic cotton or hemp-Oxford, uncoated with stone-washed finish, aligns with sustainable, artisanal brands.

Comparative Data Table

| Application | Fabric Weight | Fiber/Blend | Finish | Key Benefit |

|---|---|---|---|---|

| Promotional Tote | 4–6 oz | Cotton | None/DWR | Cost-effective, printable |

| Everyday Backpack | 6–8 oz | Cotton/Polyester | DWR | Breathable, light water resistance |

| Travel Duffel | 8–10 oz | Cotton/Nylon | PU laminate | Waterproof, structured |

| Cooler Bag | 8–10 oz | Polyester | PVC coating | Easy-clean, insulation-friendly |

| Medical Carrier | 6–8 oz | Cotton | PU laminate | Sanitizable, moisture barrier |

| Smellproof Bag | 6–8 oz | Nylon blend | Carbon laminate | Odor control |

How Do You Care for and Maintain Oxford Cloth Bags?

Care for Oxford cloth bags by spot-cleaning with mild soap and water, air-drying away from heat, and reproofing DWR finishes annually. For PU/PVC-coated areas, wipe clean with a damp cloth. Avoid machine washing heavy coatings to prevent delamination. Store empty in a cool, ventilated space to prevent mildew and maintain shape.

Cleaning Uncoated & DWR-Treated Oxford

- Spot Cleaning: Use pH-neutral detergent, a soft brush or sponge, then rinse and blot dry.

- Deep Cleaning: Hand-wash in cool water; avoid agitation that stresses basket weave.

- Drying: Hang or lay flat in shade; keep pockets open for ventilation.

PU & PVC-Coated Maintenance

- Surface Wipe: Use a damp microfiber cloth; mild soap for stubborn stains.

- Avoid Heat: Do not machine wash or tumble dry to protect laminate adhesion.

- Edge Seals: Inspect seams yearly; re-seal with compatible adhesive if separation occurs.

Reproofing & Restoration

- DWR Renewal: After deep cleaning, apply spray-on DWR; heat-activate with low-heat dryer or iron.

- PU Touch-Up: Lightly buff surface, apply thin PU re-laminate paste, smooth with spatula, cure per instructions.

- Wax Refresh: For waxed Oxford variants, apply hot beeswax/paraffin blend, heat and brush off excess.

Repair Techniques

- Patching: Interior patch with matching Oxford for tears <2 inches; reinforce with heat-bond tape for coated layers.

- Seam Repair: Sew with heavy-duty polyester thread; use seam sealer on coated fabrics to maintain waterproofing.

Storage Best Practices

- Empty & Air Out: Prevent mildew by airing damp bags fully before storage.

- Maintain Shape: Stuff with acid-free tissue or use bag forms.

- Protect from UV: Store away from direct sunlight to minimize fading.

Ready to Craft Your Custom Oxford Bag Collection?

With over 18 years of OEM/ODM excellence, Szoneier delivers turnkey solutions—from free design mockups and fabric swatches to rapid prototyping and low-MOQ runs. Whether you choose Oxford cloth, canvas, or polyester, we ensure your custom bags reflect your brand’s quality, style, and performance promises.

Contact our experts today for samples, quotes, and a seamless path from concept to finished products.Let’s turn the versatile potential of Oxford cloth into your next best-selling custom bag.